In the late 1980s the SEALs were looking for a replacement for the Mk.8 SEAL Delivery Vehicle (SDV). One of the advanced designs in circulation was the Closed-Cycle Energy Source (CCES) submersible from Perry Offshore Inc. Perry were recognized within the submarine industry for their deep submergence dry submarines typically used for underwater engineering and deep sea rescue applications. There are almost certainly the most successful mini-sub manufacturer for civilian applications like oil exploration (even if you have never heard of them!) and were the designers behind the Royal Navy's successful Vickers VOL-L1 rescue submersible (grandfather of the L5).

In the late 1980s the SEALs were looking for a replacement for the Mk.8 SEAL Delivery Vehicle (SDV). One of the advanced designs in circulation was the Closed-Cycle Energy Source (CCES) submersible from Perry Offshore Inc. Perry were recognized within the submarine industry for their deep submergence dry submarines typically used for underwater engineering and deep sea rescue applications. There are almost certainly the most successful mini-sub manufacturer for civilian applications like oil exploration (even if you have never heard of them!) and were the designers behind the Royal Navy's successful Vickers VOL-L1 rescue submersible (grandfather of the L5).

SEAL Delivery Vehicles (SDVs, aka Swimmer Delivery Vehicles) were ordinarily wet submarines, that is to say that the crew compartment was full of water so the occupants have to wear diving gear at all times. The SEALs were looking for a dry-submersible with diver lock-out capability because it would keep the men warmer and allow much longer missions. This requirement ultimately led to the Advanced SEAL Delivery System (ASDS).

Perry happened to have just such a design, and it had an advanced propulsion system to boot!

Orignal Artwork - CLICK for Higher-Resolution

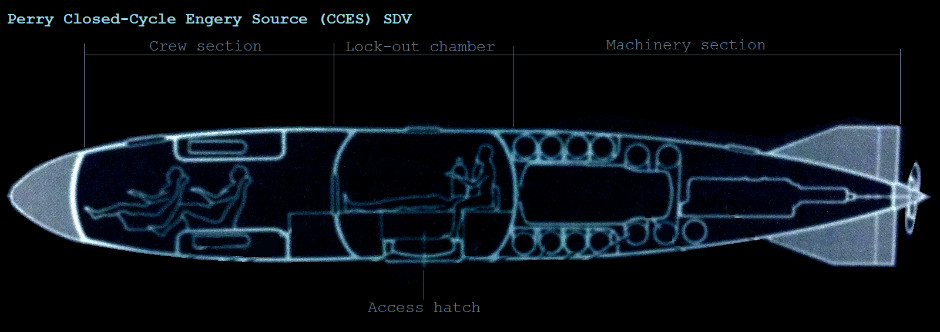

The Closed-Cycle Energy Source (CCES) was one of two Perry designs which were roughly similar except with different powerplants. These wee essentially cigar happened with pointed bows and very clean lines with a submarine-style tern arrangement. The crew sat in the front (bow) with the diver lock-out chamber amidships with a hatch to the forward section. The ear (aft) section contained the motor and was completely sealed during operations. Emergency/shore access hatches were mounted flush with the roof of all three sections. The diver lock-out section had the main access hatch in the bottom which doubled as both an exit/re-entry point during missions and a connector to the mother submarine, a lot like a rescue vehicle. This would allow it to be carried by a submarine without a Dry Deck Shelter (it was too big anyway!) but had one down side that the SDV could not be exited/re-entered whilst bottomed out on the sea floor.

The CCES version, as the name implies, would have a motor running on high-pressure propane fueled motor using liquid oxygen as an oxidizer and helium as a diluent. That is all very high tech but it would allow an incredible 300 nautical mile range. The down side to such new technology was that it was unproven, noisy (like a diesel engine in a submarine it needed rubber dampeners) and needed a cryostat plant to keep the gases liquid.

Specification

Length: 35ft (10.6m) (half the length of the ASDS!!!!)

Beam: 6ft (1.8m)

Speed: 10kts (incredibly fast or an SDV)

Operating depth: 500ft (150m)

Transit depth (uncrewed, i.e.on a mother submarine)1,300ft (390m)

Displacement: 17 tons

Range: 300nm

Team: 2 crew and 8 SEALs

Payload: 200lb (900kg)

The second version was a lower risk / lower cost proposal with a deep-discharge Lead-Acid battery powerplant. This was similar except that the aft section would be longer making it 43ft (13m) long. Speed was still 10kts but endurance was 'just' 100nm. The electric motor also meant that it was quieter than the propane-powered CCES.

The DV replacement project dragged on into the post-Cold War era and eventually led to the building of a single Advanced SEAL Delivery System (ASDS). This was much larger and ultimately too adventurous. When it was damaged bvy fire in the 2008 it was written off. It's place has since been taken by much smaller dry SDVs designed by British and Italian experts.

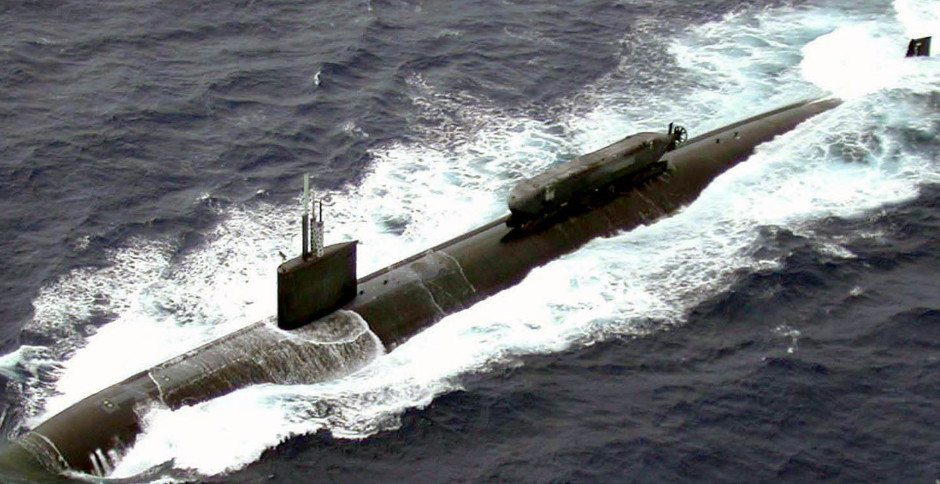

*ASDS mated with USS Greenville (SSN 772). The CCES-SDV would attach in the same way but be much smaller